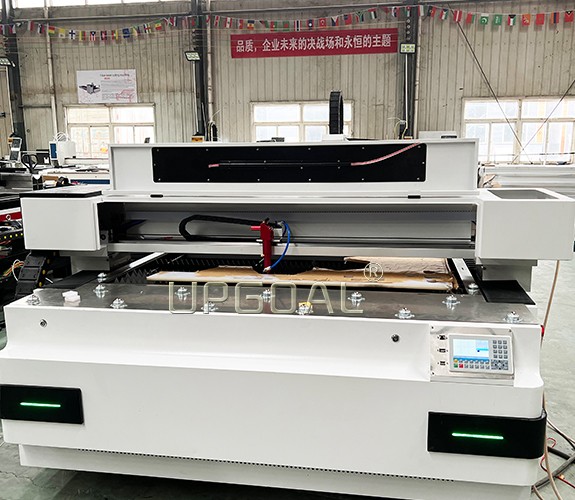

Brief Introduction:

Model: UG-1530FL-2

1500*300mm working area for both fiber & co2

Dual gantry, combined fiber & co2 laser head

2000W fiber laser source

Co2 laser 200W combined Co2 laser tube

Raytools auto focusing fiber laser cutting head

CypCut 2000& RDWorks V8 software

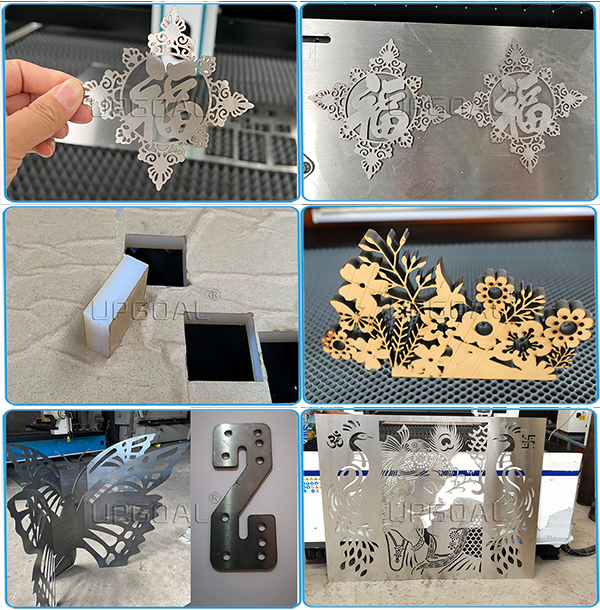

Applications

Suitable material

Cutting a wide variety of metal plates, tubes, mainly applicable to stainless steel, carbon steel, manganese steel, galvanized sheet, a variety of alloy paltes, rare metal and other materials cutting.

Application industry

Industry of kitchen ware, lamps and lanterns, panel beating, metal cabinets, auto parts, refrigerators, air condition, elevators, hotel metal supplies processing, etc.

Features

1.New Designed dual gantry combined fiber & co2 laser cutting system, one machine can cut both metal & non metal materials, each cuttting area all can be 1500*3000mm, save ccost. It is more stable than mixed CO2 laser cutter, which is mainly used for cutting metals (steel, aluminum, copper, brass, titanium, alloy, iron) and nonmetals (wood, plywood, MDF, plastic, acrylic, leather, fabric).

2.High-rigidity heavy chassis,reducing the vibration generatedduring high-speed cutting greatly. High-performance vaiation aluminium crossbeam,after finite element analysis,realizes highly accelerated circular arc cutting speed.

3.The famous RAYTools BM 110 auto focusing fiber laser cutting head does not come into contact with the surface of the material and does not scratch the workpiece.

4. Adopted stable MAX/RAYCUS brand 2000W fiber laser source, photoelectric conversion rate is high, high beam quality, work life of more than 100,000 hours, no maintenance costs.

5. Co2 laser cutting head with famous ELC brand 200W combined Co2 laser tube, with good modular & light spot, and long life time, can for thick 20-30mm non metal materials cutting.

6. With strong tooth type cutting blade table, can stand more thickness sheet , and ensure cutting performance, equipped with feeding wheels is convenient to load materials.

7. The CypCut 2000 control system for metal fiber laesr cutting is embedded with a rich memory of laser cutting setting references, flexible layout designs and tool path editing, data import/export,bridging, coedge, beam compensation, curve smoothing, division, caombination, automatic identification of exterior and interior modes and so on, compatible, with laser source brands such as IPG, SPI, JK, Raycus, etc.

8. Advanced USB port latest RuiDa 6445S DSP control system for non metal Co2 laser cutting with large inner memory device and Fast curve cutting and Optimized shortest path function, Greatly improved the working efficiency .

9. Adopted Fuji Japan 1300W & 750W servo motor and driver for machine, the servo motor with SHIMPO reducer, more accurate, It realizes closed-loop control of position, rotating speed is more faster, general rated speed can reach 2000~3000 rpm; With high strong anti-overload capability, and smooth operation at low speed, no stepping operation similar to stepper motor when running at low speed.

10 .Gantry double-drive structure,with imported Hiwin, Taiwan Linear square guide rail with ball bearing slide block which ensure high weight capacity, high precision, smooth and steady running.Taiwan YYC rack&pinion transmission system for XY-axis,improves the production efficiency.

11. Industrial CPU with moving bracelet, very convenient to operate

12. 2 Sets Industrial chiller CWUL-2000 & CW-5200(S&A Teyu ), ensuring fiber laser and laser head can be cooled quickly to ensure that the laser machine has stable power even working at high temperature, high efficient and fast operation.

13. Auto lubrication system and air blower 750W for blow- off.

14. Adopted SMC Japan proportional valve, improve cutting accuracy.

15. Open worktable, simple operation and small space eccupation.

16.High precision, fast speed, narrow slit, minimum heat affected zone, smooth cut surface and no burr.

17. The slit is the narrowest, the heat affected zone is the smallest, the local deformation of the workpiece is very small, and there is no mechanical deformation.

18.It has good processing flexibility, can process any pattern, and can cut pipes and other profiles.

19. Non-deformable cutting can be performed on materials of any hardness such as steel plates, stainless steel, aluminum alloy plates, and hard alloys.

Model | UG-1530FL-2 |

Effect cutting size for panel | 1500*3000mm |

Xaxis working area | 1500mm |

Y axis working area | 3000mm |

Zaxis working area | 200mm |

Laser type | A1:Fiber laser generator A2: Co2 sealed-off laser tube |

Laser working medium | A1: Fiber A2: Co2 |

Laser wavelength | A1 fiber: 1060-1080nm A2 Co2: ,10.6um |

Cutting head | A1: RAYTools BM110 auto focusing laser cutting head A2: Co2 cutting head |

Rated output power | A1: 2000W(MAX /RAYCUSbrand) A2: 200W( ELC brand) |

Laser cutting system | A1: CypCut 2000 A2: RuiDa RDC6445S( software: RDWorks V8) |

Driving system | Fuji Japan servo motor 1300W & 750W & 400W |

Reduction gear | SHIMPO, Japan |

Guide rail | Linear square guide rail, Hiwin, Taiwan,diameter 25mm |

Tranmission system | Helical rack and pinion transmission, YYC, Taiwan |

Proportional valve | SMC, Japan |

PositionaI accuracy | 0.03mm/m |

Repeated positioning accuracy | ±0.02mm/m |

Maximum travelling speed | 100m/min |

Power supply | AC380V, 50/60Hz, three phases or AC220V, 50/60Hz, single phase |

Graphic format supported | CAD,DXF, etc |

Lubrication system | Automatic |

Working environment | Temp:0-40℃,humidity:≤80%,No condensation |

Certificate | CE/FDA |